Understanding DTF DTG Printers: A Comprehensive Guide

What DTF and DTG Mean: Processes, Materials, and How This Guide Is Organized

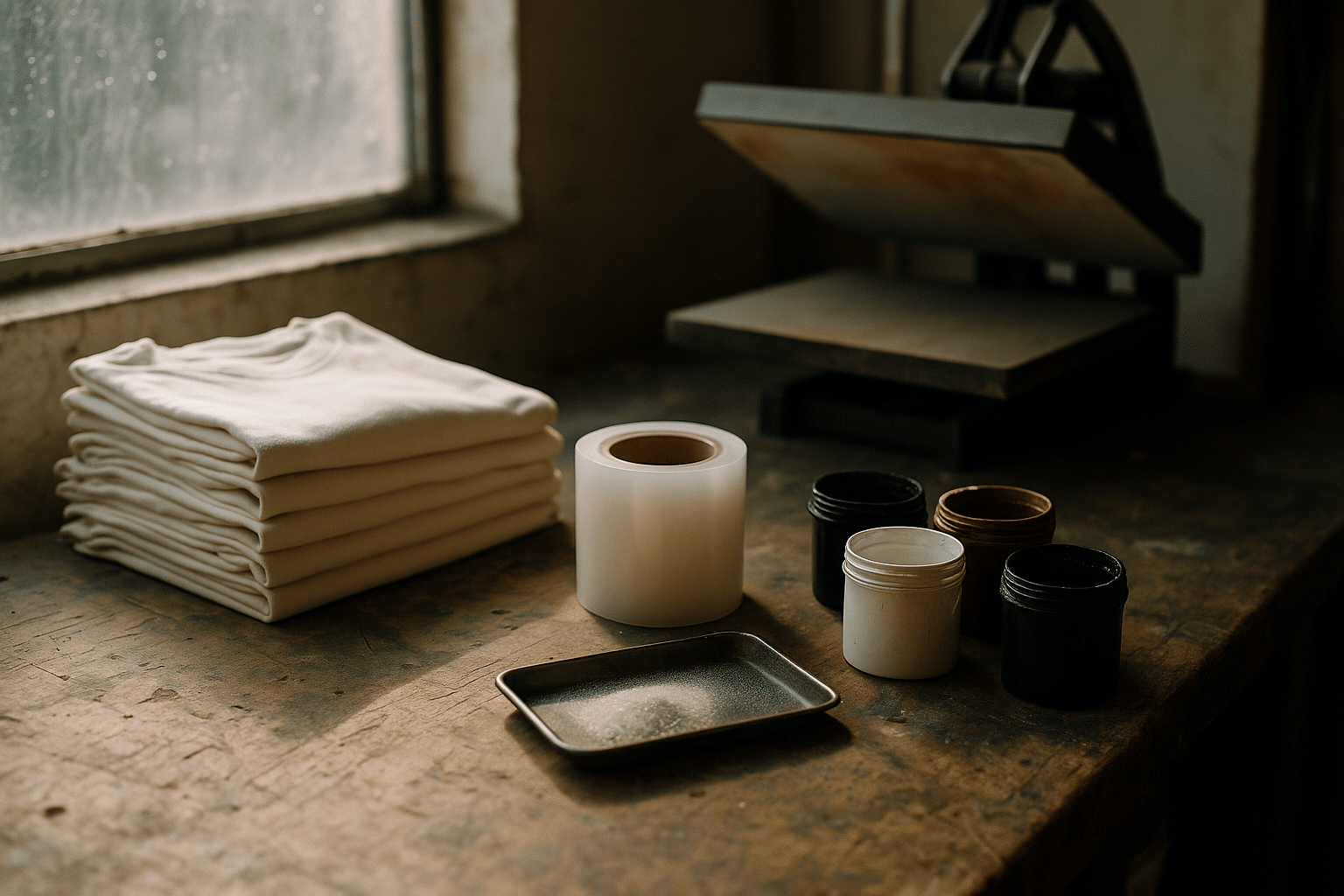

Direct-to-film and direct-to-garment are close cousins in modern textile decoration, but they take different routes to reach the same destination: a wearable, durable print. With direct-to-film, water-based pigment inks are printed onto a coated PET film in reverse, then covered with a finely milled hot-melt adhesive powder. After a brief cure, the transfer is heat-pressed onto the fabric, the film is peeled, and a quick post-press locks everything in. Direct-to-garment prints straight onto the fibers, often with a white underbase on dark items, and then the ink is heat-cured so pigments bond to the material. In day-to-day use, these differences affect how you schedule jobs, what fabrics you can serve, the feel of the print, and the type of quality control that keeps customers returning.

Here is the outline for what follows, so you can jump to what matters most in your shop:

– Processes at a glance and the materials involved

– Quality and durability: color, handfeel, stretch, and wash performance

– Fabric compatibility and real-world use cases

– Workflow, throughput, and cost modeling for small and growing operations

– Maintenance, sustainability, and buying considerations (conclusion)

Process snapshots help illustrate why both methods have a place. Direct-to-film excels at versatility: cotton, polyester, blends, and many tricky placements benefit from transfers you can stock and press on demand. Transfers can be batched, ganged on sheets, and stored, which gives micro-brands and print-on-demand sellers a nimble way to handle spikes in orders. Direct-to-garment shines when you want a soft, nearly fabric-like handfeel on cotton-rich garments, fine gradients, and photographic detail without a transfer layer. Because ink meets fiber, the result can feel integrated into the knit rather than sitting above it, especially on lighter garments.

From an operator’s perspective, you juggle a similar set of variables in both methods: ink chemistry, textile type, underbase opacity, dwell times, and pressure or curing temperatures. Typical transfer presses for direct-to-film run around 150–165°C with 10–20 seconds of pressure, while direct-to-garment curing often targets comparable temperatures with a longer dwell to drive out moisture and fully bind pigment. Managing those numbers is part art, part science, and when you get them right the difference shows up in a customer’s laundry basket weeks later. The sections ahead translate these choices into practical outcomes, with examples you can adapt to your own workflow.

Quality and Durability: Color, Handfeel, Stretch, and Wash Performance

Quality is the first impression; durability is the last word. Direct-to-film often produces bold color on dark garments because a dense white underbase is easy to lay down on film before transfer. That underbase gives you strong opacity and edge definition, which is useful for graphics with solid fills or high-contrast logos. The trade-off is a perceptible film layer, especially over large areas, that can feel a bit more structured than the surrounding fabric. Direct-to-garment, by contrast, wins for tactile subtlety on cotton-rich textiles. When pretreatment is dialed in, colors are vibrant and gradients feel naturally integrated, with the knit texture still visible through mids and highlights. On light shirts, a CMYK-only pass can look airy and soft to the touch.

Wash and wear tell the longer story. With proper application and a compatible powder adhesive, direct-to-film transfers can routinely endure dozens of household cycles while maintaining color density. Good practice is to wait 24 hours before washing, turn garments inside out, and avoid excessive heat in the dryer. Direct-to-garment wash performance varies more with garment quality, pretreatment accuracy, white-ink laydown, and curing discipline. When all of those are well controlled, long-lasting prints are achievable on cotton, keeping edges crisp and colors stable across many wears.

Stretch response is another differentiator. Direct-to-film forms a bonded layer that can flex with knits, but heavy stretching over wide solid areas may lead to visible stress lines with time. On intricate, smaller graphics the effect is minimal. Direct-to-garment relies on pigments anchoring inside the fiber structure, so moderate stretch often shows less surface cracking, though extreme deformation can still stress the ink and fibers together. Breathability also tips toward direct-to-garment on large coverage prints since there is no intermediary film; direct-to-film’s solid areas can feel warmer on the body in hot weather.

For quick reference, consider these practical signposts:

– Need brilliant opacity and registration on dark performance fabrics: direct-to-film is often a strong fit

– Want a premium soft hand on high-cotton tees with photo detail: direct-to-garment is well-regarded

– Printing small badges or tag-sized marks in batches: direct-to-film enables efficient gang sheets

– Large, full-front photographic art on ring-spun cotton: direct-to-garment delivers an elegant, textile-like finish

The upshot is that both paths can produce outstanding results; they simply excel in different ways. If your customers prize buttery handfeel and natural drape, you may lean toward direct-to-garment for signature pieces. If they demand bold opacity across varied fabrics, direct-to-film provides dependable impact, especially for modular, repeatable graphics.

Fabric Compatibility and Use Cases: Cotton, Blends, Polyester, and Tricky Surfaces

Direct-to-film earns its reputation for versatility by transferring to a wide range of textiles with consistent adhesion. Cotton, polyester, and poly-cotton blends are common targets, but transfers also adhere to many nylon windbreakers, canvas totes, and caps with structured panels. Because the artwork is pressed on with heat and pressure, placements that are difficult to load onto a platen—like sleeves, pockets, and bag flaps—are often easier to handle with a transfer workflow. You can also stage seasonal designs as ready-to-press sheets, keeping fulfillment nimble when demand surges.

Direct-to-garment thrives on cotton-rich fabrics, where the pretreatment allows white ink to sit up on the fibers and color layers bond reliably. Ringspun and combed cotton garments typically yield a smoother, more premium surface for photographic prints and soft gradients. While polyester is possible in some cases, it demands care: lower cure temperatures, dye-migration blockers, and fabric-specific pretreatments are often required to avoid color shifts or muted whites. That additional complexity can be well worth it for short runs of breathable, soft-feel prints on athleisure items made with cotton blends.

Match methods to demands using use-case thinking:

– Streetwear drops with variable fabrics and rapid restocks: direct-to-film provides flexible inventory through stored transfers

– Limited-edition art tees with nuanced tones: direct-to-garment delivers a refined, fabric-integrated look on cotton

– Corporate or club merch where names, numbers, and small repeats recur: direct-to-film scales efficiently via gang sheets

– On-site personalization at markets: either method works, but preprinted direct-to-film transfers speed lines with quick presses

Tricky textures deserve a note. Heavy fleece, terry, and coarse weaves can challenge fine detail with direct-to-garment because ink must bridge valleys in the pile. A smoother surface—achieved with a pre-press or selecting tighter knits—generally improves results. Direct-to-film transfers, with their own cohesive layer, often span those textures more cleanly, though you will want firm, even pressure to avoid incomplete adhesion in low spots. For caps and thick seams, transfer techniques with purpose-made pressing pads can help distribute pressure and protect the shape of structured items.

In short, think like a fabric strategist. If your catalog spans everything from soft cotton tees to synthetic outerwear, direct-to-film can cover more ground with fewer process changes. If your catalog leans toward premium cotton apparel with art-focused prints, direct-to-garment rewards that focus with elevated feel and tonal nuance.

Workflow, Throughput, and Cost: From First Click to Finished Shirt

Speed is a chain, not a single link. Direct-to-garment generally follows this sequence on dark garments: pretreat, dry or press the pretreatment, print a white underbase and colors, then cure. Pretreatment takes seconds to apply but minutes to dry if air-drying; a press can shorten that to under a minute while also flattening fibers for sharper detail. A typical A4 to A3 graphic might print in 1–5 minutes depending on resolution and coverage, followed by 2–3 minutes of curing at around 150–160°C. The upside is a streamlined, immediate path from art to garment with no intermediate film. The limiting factor is prep and cure time, which you can mitigate by staging pretreated blanks and curing in batches.

Direct-to-film introduces a transfer stage but gains flexibility. The chain is: print the film (mirrored), apply powder, cure the adhesive for roughly 2–3 minutes until it gels or turns glossy, press onto the garment for 10–20 seconds at about 150–165°C, peel according to the film’s characteristics, and often post-press for a few seconds to improve wash performance. When you batch prints on gang sheets, the press step becomes the fastest link, with per-garment pressing times measured in seconds. That makes pop-up fulfillment, remote decoration partners, or multi-location pressing feasible with consistent quality, since the most variable steps happen upstream in a controlled space.

Cost is a mix of materials, time, labor, and rework risk. Direct-to-garment consumes pretreatment and ink directly on the garment; a dark shirt may use several milliliters of white ink plus CMYK, with consumption scaling to coverage and profile settings. Direct-to-film uses ink on film plus powder and the film itself; the film area drives cost more than garment size once you are ganging multiple images. While specific numbers vary by supplier and region, many shops track per-print materials in the low single digits for both methods on typical graphics, then layer in labor, energy, and spoilage. Efficiency tactics include: dialing white-ink underbase to the minimum that still gives clean color, optimizing artwork to reduce unnecessary coverage, and right-sizing curing times to avoid bottlenecks without under-curing.

Throughput-wise, two practical patterns emerge:

– Small, same-day runs on cotton-rich garments with nuanced art: direct-to-garment offers a clean, single-surface workflow

– Mixed-fabric orders or remote pressing teams: direct-to-film transfers allow centralized printing and decentralized finishing

Finally, remember that speed is nothing without reliability. A 60-second cure saved today can become a return request after the third wash. Time your processes, log your settings, and standardize your blanks where possible; the payoff is predictable cycle times and fewer surprises when orders stack up.

Maintenance, Sustainability, and Buying Considerations: A Practical Conclusion

Maintenance is the silent partner of print quality. Both methods rely on water-based pigment inks, and white ink in particular benefits from daily circulation and regular agitation. Routine tasks include nozzle checks at the start of a shift, capping-station cleaning, and keeping humidity in a comfortable mid-range to prevent premature drying in lines. For direct-to-garment, pretreatment stations and platens need wiping to avoid residue buildup that marks garments. For direct-to-film, powder-management is vital; stray granules around curing areas can re-melt and contaminate surfaces, so a clean bench and dedicated trays pay off quickly. Store films flat, away from dust, and clearly segregate hot and cool peel stocks to prevent mix-ups during pressing.

Sustainability considerations differ by method. Both use water-based inks with relatively low volatile emissions compared to many solvent systems, and both reward accurate curing that avoids rework waste. Direct-to-garment has minimal solid waste but can generate pretreatment runoff if carelessly handled; using measured applications and designated cleanup procedures helps. Direct-to-film produces PET film offcuts and backing sheets; reduce waste by ganging designs, optimizing nesting, and trimming efficiently. On-demand production—in either method—reduces overstock and dead inventory, which is often the largest environmental win for small brands.

When evaluating equipment and the workflow you will build around it, consider:

– Your core fabrics and where you want to grow (cotton-forward vs mixed synthetics)

– Typical order sizes and how often you repeat the same graphic

– Available space for curing, powder handling, and ventilation

– The level of operator experience and appetite for process tuning

– Desired handfeel vs required opacity on dark garments

For many new shops, a hybrid approach emerges naturally. Use direct-to-garment to elevate flagship cotton tees with soft photographic prints; keep a stock of direct-to-film transfers for bags, caps, polyester teamwear, and quick-turn repeat graphics. As volume grows, you can specialize in what your customers love most while keeping the flexibility to say yes to diverse requests. Above all, chase consistency: document settings, keep consumables fresh, maintain your hardware, and test new blanks before a big release.

Conclusion for apparel entrepreneurs and print teams: start with your catalog, not the machine. If your customers want supple, art-forward cotton pieces, direct-to-garment is a natural anchor. If they expect bold color across varied fabrics and placements, direct-to-film adds a reliable, scalable tool. Build standard operating procedures, price with realistic cycle times, and choose the path—or combination—that makes your shop steady, responsive, and ready for the next drop.